Products

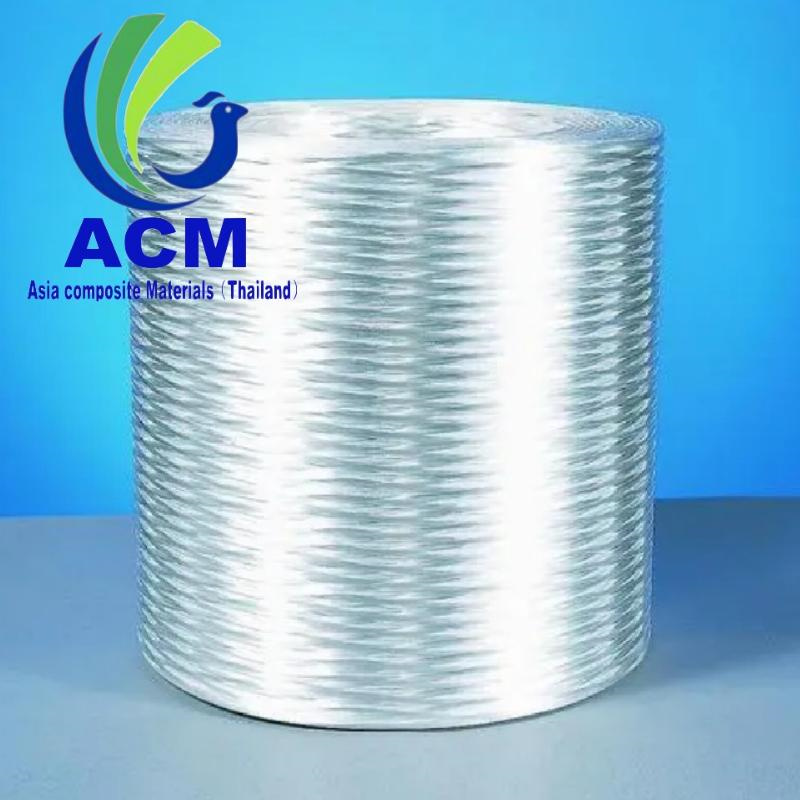

ECR-Fiberglass Direct Roving for LFT-D/G

Direct Roving for LFT-D/G

Direct roving for LFT-D/G is based on silane reinforced sizing formulation. It's known for excellent strand integrity & dispersion, low fuzz & odor, and high permeability with PP resin. Direct roving for LFT-D/G provides excellent mechanical properties and heat resistance of the finished composite products.

product specification

|

Product Code |

Filament Diameter(μm) |

Linear Density(tex) | Compatible Resin | Product Features and Application |

|

EW758Q EW758GL |

14、16、17 |

400、600、1200、1500、2400 | PP | Good strand integrity and dispersionLow Fuzz and odor

High permeability with PP resin Good properties of the finished products Mainly use in industries of automotive parts,building &construction,electronic & electrical,aerospace etc. |

|

EW758 |

14、16、17 |

400、600、1200、2400、4800 | PP

|

Direct Roving for LFT

Direct Roving for LFT is coated with silane-based sizing agent and compatible with PP, PA, TPU and PET resins.

LFT-D: Polymer pellets and glass roving are introduced into a twin-screw extruder where the polymer is melted and compound is formed. Then the molten compound is directly molded into the final parts by injection or compression molding process.

LFT-G: The thermoplastic polymer is heated to a molten phase and pumped into the die-head. The continuous roving is pulled through a dispersion die to ensure the glass fiber and polymer impregrated completely to get consolidated rods, then cutting into final products after cooling.