Products

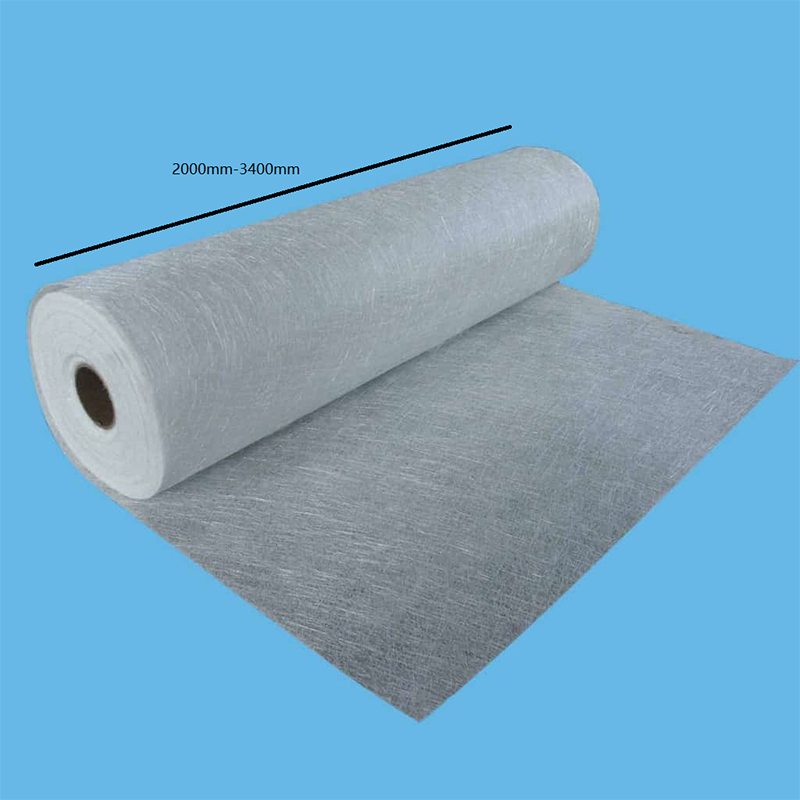

Fiberglass Customized Big Roll Mat(Binder: Emulsion & Powder)

Application

Fiberglass Customized Big Roll Mat, a crucial component in the realm of Fiber Reinforced Plastics (FRP), find extensive application across various industries. These versatile mats are predominantly employed in processes like automated lay-up, filament winding, and molding to create an array of exceptional products. The applications of Fiberglass Customized Big Roll Mat span a wide spectrum, encompassing the manufacturing of large carriage plate,such as refrigerated truck,motorhome van and much more.

| Weight | Area Weight

(%) |

Moisture Content

(%) |

Size content

(%) |

Breakage Strength

(N) |

Width

(mm) |

|

| Method | ISO3374 | ISO3344 | ISO1887 | ISO3342 | ISO 3374 | |

| Powder | Emulsion | |||||

| EMC225 | 225±10 | ≤0.20 | 3.0-5.3 | 3.0-5.3 | ≥100 | 2000mm-3400mm |

| EMC370 | 300±10 | ≤0.20 | 2.1-3.8 | 2.2-3.8 | ≥120 | 2000mm-3400mm |

| EMC450 | 450±10 | ≤0.20 | 2.1-3.8 | 2.2-3.8 | ≥120 | 2000mm-3400mm |

| EMC600 | 600±10 | ≤0.20 | 2.1-3.8 | 2.2-3.8 | ≥150 | 2000mm-3400mm |

| EMC900 | 900±10 | ≤0.20 | 2.1-3.8 | 2.2-3.8 | ≥180 | 2000mm-3400mm |

Capabilities

1. Highly effective mechanical qualities and random distribution.

2. Excellent resin compatibility, a clean surface, and good tightness

3. Excellent resistance to heating.

4. Increased wet-out rate and speed

5. Conforms to difficult shapes and fills molds with ease

Storage

Products made of fiberglass should be kept dry, cold, and moisture-proof unless otherwise stated. The humidity in the room should constantly be kept between 35% and 65% and between 15°C and 35°C, respectively. If possible, use within a year after the manufacturing date. Fiberglass items should be used right out of their original box.

Packing

Each roll is automated lay-up and then packed in a wooden pallet. The rolls are stacked horizontally or vertically onto pallets.

All pallets are stretch wrapped and strapped to maintain stability during transport.